Driving Sustainability

Copyright and Photographer should be quoted: (C)FSG - Leon Haindl

At Formula Student Germany, staying ahead of the curve isn’t just part of our DNA—it’s our commitment to shaping the future of mobility by educating the next generation of engineers, thought leaders and decision makers. As the automotive industry undergoes a transformative shift, one topic continues to gain speed: sustainability.

Driven by evolving social values and stricter regulations, companies across the sector are racing to meet ambitious CO₂ reduction targets. Even Formula 1 has pledged to be net zero by 2030. This is why FSG has introduced the Costed Carbonized Bill of Material (CCBOM) as latest challenge in the Cost & Manufacturing Event. Additionally, to the cost calculations, teams will now calculate the CO₂ emissions—expressed in CO₂ equivalents—of one race car system using a Cradle-to-Gate analysis.

The CCBOM in detail: CO₂ calculation for Formula Student Germany

For the 2025 season, the Cost Report Documents consist of a BOM including the CCBOM, the Supporting Material File and the Cost and Emissions Explanation File. As the calculation of greenhouse gas emissions, expressed as carbon dioxide equivalents (CO₂e), at the material, process, tooling, and fastener levels, is a new requirement for all teams, the following explanation outlines a calculation example to provide guidance.

Calculation Example:

Start by defining system boundaries and collect data about the part of interest. Think about where to get access to useful, valid resources like scientific papers, data sheets or norms. While tools like ChatGPT can be useful for gathering initial information, they should not be the sole source of truth.

Step 1: Raw Material Extraction e.g. Aluminum incl. material production and transport

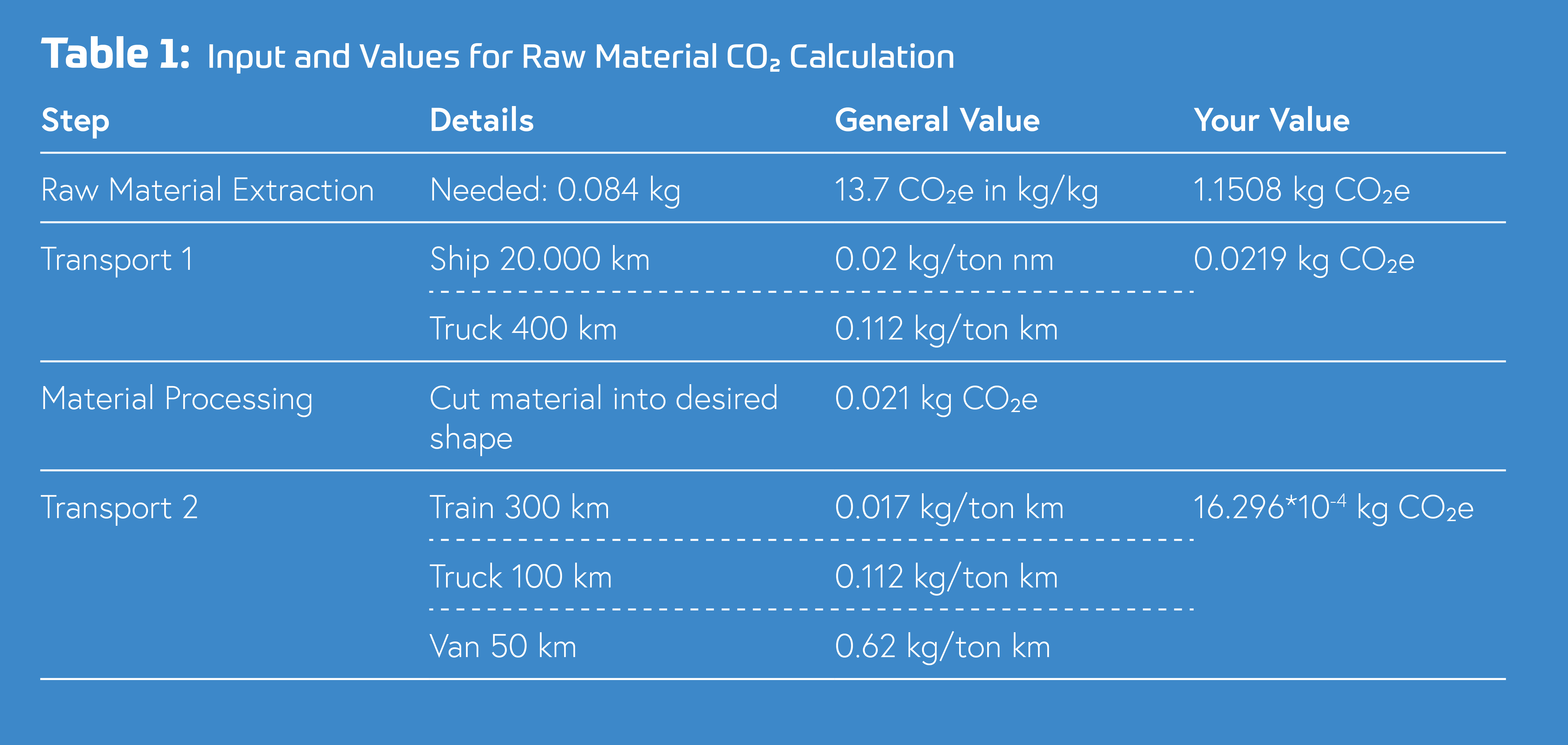

The first step is to account for raw material extraction, using aluminum as an example. This includes not only the production of the material itself but also its transportation. The calculation should consider the origin of the raw material, how it is extracted and prepared, and the various modes of transport involved, such as shipping and trucking, from the extraction site to a reseller and then from the reseller to your workshop, which might involve trains, trucks, or vans (see Table 1).

Step 2: Manufacturing of Parts

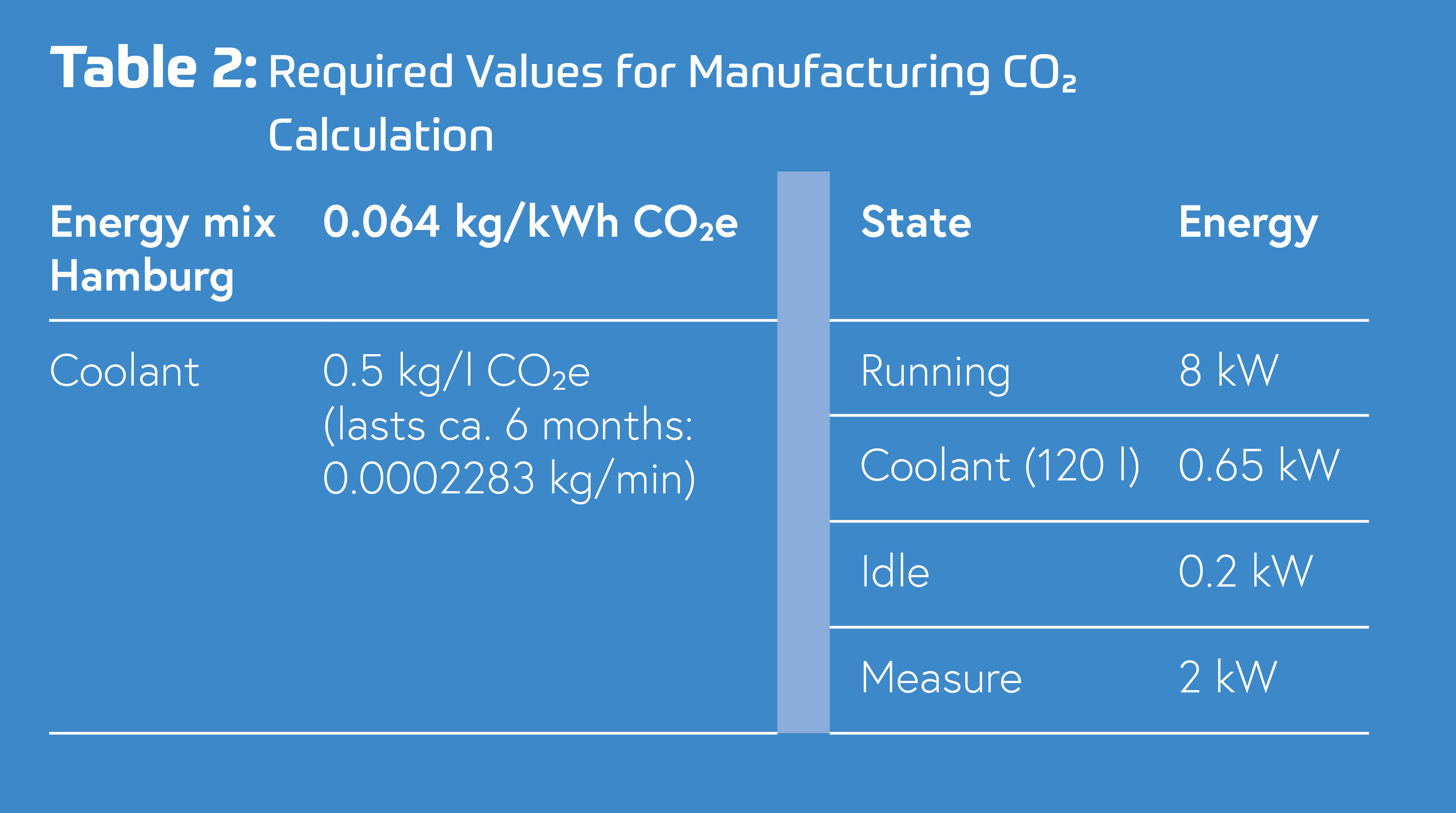

Once the raw material arrives at the workshop, the second step focuses on the manufacturing of parts. This involves calculating the emissions associated with setting up and operating machinery, such as milling machines. Each phase – initial setup, setup changes, and part removal – should be considered, along with the actual machining operations like milling or drilling. For each step, it is necessary to detail the time required, the resources consumed, and any additional factors, such as the use of coolants. The energy consumption for each machine state must be identified, along with the local energy mix and the CO₂ value of additional materials like coolants (see Table 2). The CO₂e for energy consumption is calculated using the formula:

Energy [kW] x Duration [h] x 0.064 kg/kWh.

Step 3: Additional Considerations

Additional considerations must also be included. These cover all other resources needed to build a race car in the workshop, such as electricity for lighting, space for storing parts and materials, heating, and even the travel emissions from team members commuting to the workshop. As an example, the calculation of CO₂e for energy consumption requires the values of general consumption for lighting in W/m2, the space occupied by your machine in m2 and the space needed for a team member to execute a hand finish in m2, resulting in the formula:

kW/m2 x Space [m2] x Duration [h] x energy mix [kg/kWh].

Summary

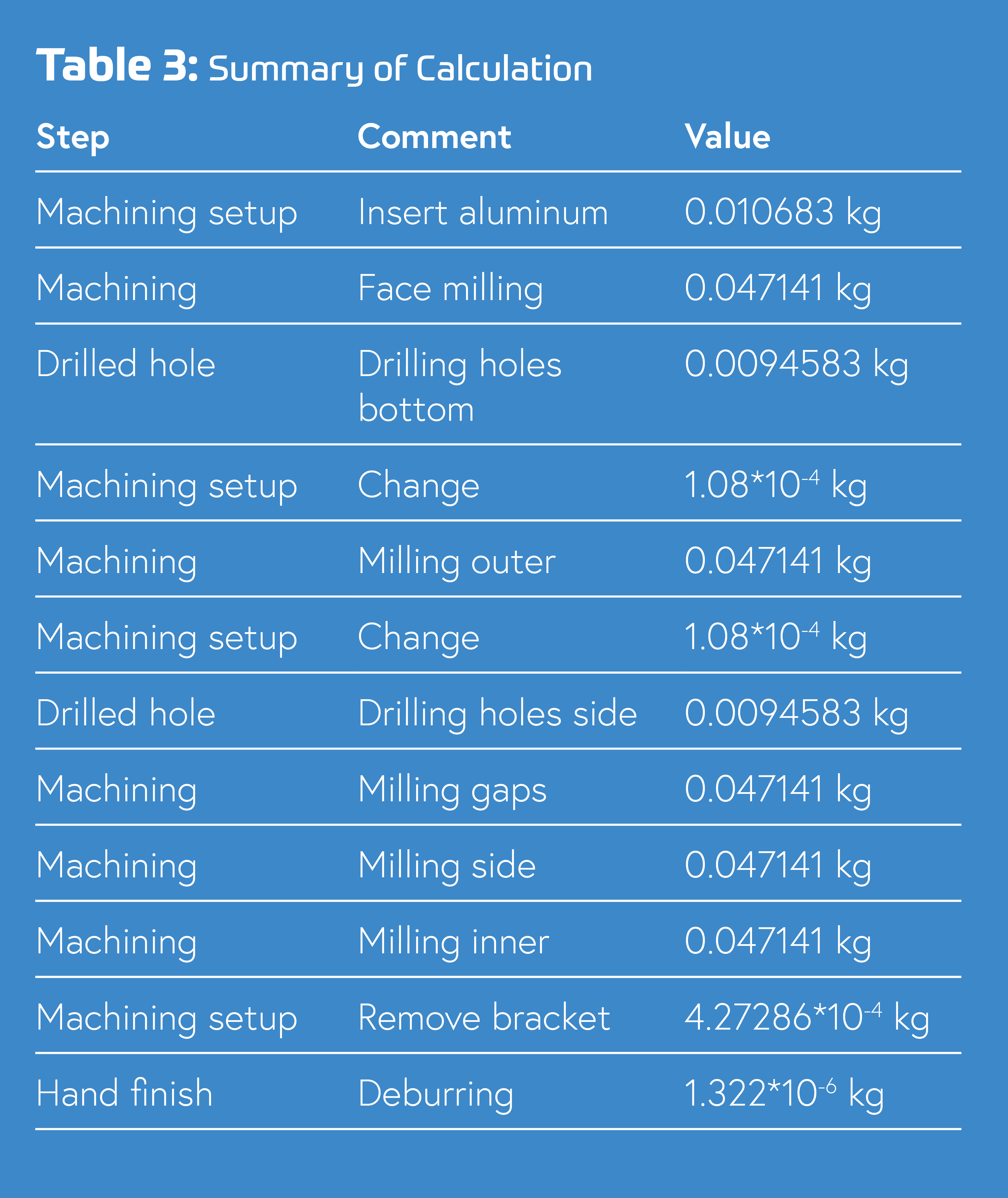

All these details are then brought together to present a comprehensive and detailed justification of the assumptions made (see Table 3). The more precise and transparent the calculations and justifications, the better.

What you should keep in mind

- New split of systems: Make sure to have an explanation why certain assemblies are put in one or the other system

- Inputs: Use the inputs provided by the FSG tool

- Understand the definition of bought parts: Silicon hoses by the meter are bought parts. Specific and already cut CFRP rods for the suspension system are made parts.

- Understand what kind of changelog is allowed and prepare it

accordingly (if necessary) - Supporting Material File: As it is limited to 20 pages, think about what is really necessary for your Cost and Manufacturing presentation to be visualized in drawings etc.