Hello, I have been invited by the organisers of FSG to become a Technical Advisor to the teams involved. Part of my responsibilities will be to write a regular Newsletter bulletin article.

A little introduction is in order. I first became aware of FSAE in 1994 whilst on a business trip to the USA. At the time, I was part of the FIA/CIK (Karting) commission at the time, and was having conscience attacks about the damage that Karting was doing to the educational development of young karters, and when I discovered FSAE, I was instantly attracted, and returned again to see the competition in 1996. I have been involved ever since, and was a part of the introduction of FSAE to Australia in 2000. I am regularly a senior Design Judge at FSAE and FS.

I have been mentoring various FSAE teams for many years, and the FSG organizers have requested that I help the entrants in this new competition. I am thrilled to be asked, and I look forward to hearing from all teams over the next few months.

Over the past few years I have answered dozens of technical questions from FSAE and FS teams. One of the most common is "What sort of chassis should we build", or, "We have designed our chassis and now we are looking for an engine or wheels or something". My response is never to tell the team what to do (That is not my job) but to ask instead "What is the chassis"? I never get the right answer which is "The chassis is a bracket that holds the whole car together".

Accepting that the chassis is simply a complicated bracket, then how is it possible to design the chassis before all the other parts have been chosen? In fact, the chassis is almost the last component designed. If a team selects and measures all the attachments to the "Bracket" (including the driver) and enter all the data into a CAD program, when everything is entered, then the chassis almost designs itself! The best solutions can be described as "Elegant" as this is where Engineering meets Art.

The FSG project is like a circle, that is, there is no beginning or end to the project. Every decision affects every other decision, and it is the elegant solution to this conundrum that the judges want to see. Regularly I hear that the judges did not like some aspect of a car or design. I am sure this is a communication error. When a judge asks "Why did you do that"? he is not being critical or disagreeing with your design logic. Rather, he wants to know WHY that decision was made.

The judges get to read your design review and then look at your car. They have all seen lots of cars so they know what they are looking at. What will advance you in the Design Competition is being able to adequately defend your design. Whether your solution is the same as the judge would adopt is immaterial. The legitimacy of the design will be proven on the racetrack.

New Feature

In each bulletin I will feature a picture of a design error from some previous team. (No, I will not tell you who it was.) I will then explain why the judges would not like such a solution. Hopefully, this will help teams avoid similar errors in their designs.

Error No. 1

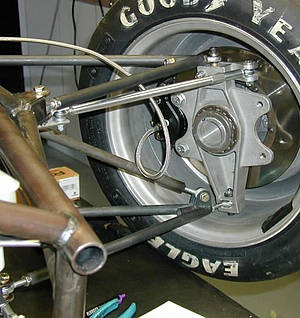

This picture shows a classic design error that all Judges hate, and is considered a "Mortal Sin". Every year several cars are presented like this as teams ignore the advice or directions they are given.

The outer spherical bearings are threaded rod ends loaded in bending! The entire mass of the car, plus bump loads, weight transfer and brake torque are reacted to the chassis by bending the threaded shank of the lower joint. This is going to break! GTB! Do not do this!

The upper rod end is being asked to react brake torque in bending. It is also being carried in single shear on top of the upright. These errors are not so serious, but still examples of poor design.

The judges understand why teams do this. It makes camber adjustment easy, but there are better solutions. Teams will argue they have selected a rod end with sufficient bending capacity, but this argument will not hold with the judges. A Rod end with a sufficiently strong shank will be far too big and heavy, and as the thread roots are good stress raisers, the joint will probably crack and break anyway. In any case, we are talking about the Design Competition, and incorrect use of fasteners is not good design.

Some teams may build a set of adjustable suspension arms like this for testing. It enables them to determine optimum camber (and/or caster) angles, but when their testing is complete, they build a more appropriate set of components for the competition.

The inevitable consequence of bending rod end shanks is this!

Until I see you again next month,

Good luck in your designing