Warning! Historical stuff!

I am often asked where I learned about this race car design stuff. Students want to know if they can learn the same way. The simple answer is ‘No’ because times and places have changed and we must change with it.

When Carroll Smith recruited me as a Design Judge in 1998, I was a VP in the FIA’s Karting Commission with responsibility for technical matters and many people thought this experience was what qualified me. But in discussions with Carroll during my ‘interview’ we hardly talked about karting, rather we discussed what I understood about race car design, physics and dynamics.

I was always race car mad. In the 1950s in Europe, if someone wanted to build a race car, money was short and ‘donor’ cars were both dull and hard to obtain.

In the UK, the 750MC fostered the building and racing of simple cars based on the old pre war Austin 7 (750cc) and the later Ford 10s (1172cc) cars. These engines were low powered side-valve engines attached to 3 speed transmissions, yet the cars they powered were fast beyond their specification.

These classes fostered a host of brilliant designers, many of whom went on to design race winning cars in Formula 1. Think of names like Chapman, Broadley, Southgate, Terry, Philippe etc, and you get the idea. Unfortunately, not ‘Clarke’, I am not remotely in the same league as those guys!

This hotbed of design was limited, more or less, to the UK, so living in Ireland, I only got to see those cars when they came to race locally at Wicklow, the Curragh or in the Phoenix Park in the middle of Dublin city, where my dad would take me to spectate (invariably in the pits).

I recall the first car the intrigued me was called the Empire Special. This elegantly simple car , powered by a 750cc supercharged engine) literally blew away much more expensive sports cars like Jaguars and Maseratis to win the Leinster Trophy race in 1955 (I was 10 and already asking ‘Why’?).

The Empire Special was actually a prototype Lotus Mark Six, forerunner of the Lotus 7, what we now know as a ‘clubman’ car.

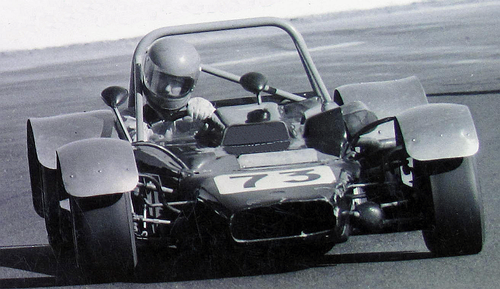

Right is a horrible little picture of the car I found on David Piper’s Facebook site.

Right is a horrible little picture of the car I found on David Piper’s Facebook site.

The usual Ford specials of the time had a beam front axle but the Six had the axle cut in half and pivoted as swing axles. Why? I asked and probing and thinking about it, I began to realise the importance of keeping the tyres on the road.

Why, I asked, was the Six so fast with such a little engine? “Oh, it’s the supercharger” I was told, so off to the library I went to learn about superchargers. There I was introduced to the wonderful world of aero engines and why they were supercharged. I developed a simple equation (not far wrong, even today!) that a properly supercharged engine would make twice as much horsepower, so the 750cc Six had the power of a 1,500 engine, more or less.

But, the Jaguar D Type engine was over twice that size! There had to be other answers and I figured out they were weight and roadholding. And so the road to discovery went on, page by page, lightbulb by lightbulb. I always had a sneaky admiration for those simple clubman cars that offered so much performance for so little cost. They would come back into my life again several times in the future.

Being there at the beginning meant I could watch the development of these cars and my enquiring mind kept me asking ‘Why would they do that’ ? An example was the Mallock U2 cars of the mid 1960s that were the fastest clubman cars of the day while still keeping to the simple formula.

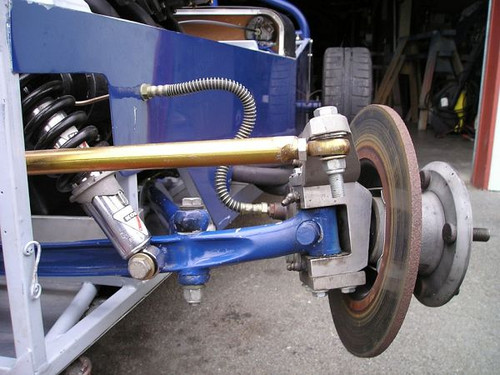

Mallock U2 swing axle front suspension

Mallock didn’t split the beam axle in half, he used two beam axles, cut the ends off and pivoted each half axle on the opposite side of the car! That introduced me to the idea that the swing axle length and therefore why camber compensation when the car rolled was important. But the swing axle length was limited to the width of the chassis, so the double A arm suspension geometry. then commonplace on open-wheelers became easier to understand. Not as in what it did, but why it did it!

Each development was like turning over another page in a book I could not put down. Always I was looking for the answer to ‘Why?’ which is why I terrorise the FSG competitors with this exact question as a Design Judge.

Another part of the clubman design formula was the cars had to use a standard rear axle assembly from a production car. Depending on what donor car was used, the usual axles came from Ford, Triumph or BMC cars. The Six in Wicklow used the axle from a Ford van and I soon figured out why. That axle had an offset differential housing, allowing the driver to sit beside the driveshaft, rather than over it. Lowering the driver lowered the centre of gravity and yet another page was illuminated.

No production car used a limited slip differential. In those days I had never heard of such a thing. Having my dad help me figure out how a standard differential worked was a time I remember well. That led me to understand why some cars spun one rear wheel when accelerating, but I had to ask myself why some cars did not suffer from wheel spin, they just went fast.

I recall submitting a Physics homework exercise showing how Newton’s third law could be used in practical situations, using the loads in the radius arms of a U2 sports car as an example. I though the example was brilliant, unfortunately Brother Arnold did not agree. I never did like him. But thinking about the problem, I began to understand torque reactions and went back to the library to read those aircraft books again. Big propellers do strange things to the airframe.

So, this was a learning exercise that was spread over many years and with study examples in motorsport and aviation being thrown up repeatedly for me to wonder about.

At FSG we are asking the young designers to understand all these subtleties in a very short time and so I really admire those that do!

By that stage, there were some books available that dealt with chassis design and suspension dynamics, my favourites being ‘Racing and Sports-car Chassis Design’ by Frank Costin and David Phipps (long out of print, but .pdf versions are available on line) and ‘High Speed, Low Cost’ written by our sadly departed friend, Allan Staniforth.

Inevitable, I suppose, but I was destined to design my own car.

That didn’t happen until I had moved to Australia, where I found CAMS, the local motorsport authority, had embraced the clubman formula.

Slightly different to the 750 and 1172 formulae cars in the UK, CAMS required engine, transmission, brakes and rear axle to come from a production car (but not necessarily the same car). The car was to be of ‘non aerodynamic shape’ with a maximum engine capacity of 1,300cc, lifted to 1,500cc several years later.

They say ‘Birds of a feather stick together’ and I soon found a couple of guys who had a bootlegged set of Mallock U2 drawings and wanted to build one. Studying these drawings, I quickly came to the conclusion that the design was way out of date and would struggle with the power of the 1,300 OHC engines and the racing tyres that were permitted.

So, working for Yamaha on their AG Bike development in the daytime, I ‘drew up’ what I considered a much better design car in the evenings. I use the term ‘drew up’ deliberately because it meant something different then than it does now. There were no personal computers, let alone CAD software, so ‘Drew Up’ actually meant ‘Design’, whereas it does not necessarily mean that today.

The CAMS rules alluded to a ‘Road going sports car that could be raced successfully on the weekend’. I read this as ‘An out and out racing car that could possibly be driven on the road if you were absolutely desperate’. This car was never going to see any road work!

The first decision was to choose what tyres we would use. I smile when I read FSG Design Reports that tell me 40 years, nothing has changed. Initially, I wanted to use 10” diameter wheels, using tyres designed for racing Minis at the time. I soon found that tyres suitable for thrashing on a FWD car were not suitable for a lightweight RWD sports car.

I also found there really was not enough space inside the 10” wheel for a good brake package and outboard suspension components.

The selection of 13” wheels meant we could use tyres designed for Formula 3 cars and to cut costs, we could practice on second hand Formula Ford tyres. Deeming the U2 crossover suspension unsuitable, I looked at a traditional double A Arm design. I wanted a longer virtual swing axle length to keep the tyres upright under hard braking, and I didn’t want to react the braking torque through the spindly swing axle. I had access to a Brabham BT18, and the front suspension on that car was my inspiration as I always respected Ron Tauranac’s designs.

I understood I couldn’t just copy the design as the rear roll centre was going to be high with the live axle. Using my version of Stannie’s ‘string computer’, I was soon able to alter the design to lengthen the VSA to 2xtimes track width (the BT18 VSA was 1.5 times) and to lift the roll axis to where I was happy. Not so high as to cause excessive jacking, but high enough that I didn’t need excessively thick anti roll bars.

The rear suspension used a standard BMC axle from a Morris Major, but converted to disc brakes. The axle was located by four equal length and parallel radius arms and a single panhard rod. We checked there was no bump steer or roll steer over the range of suspension movement we had. The upper end of the Girling coil-over dampers located on the top of cockpit rear bulkhead. On the revised chassis, we moved this pickup point to the roll hoop vertical members.

The front uprights were Standard Triumph and the brakes were from a Triumph 2000 saloon. Although every man and his dog used the ST uprights, I was still a little worried about reacting the brake torque through them, so we welded on some gusset plates to stiffen them.

The transmission was from a Triumph Spitfire with a close ratio, straight cut gear set. The tail housing of the gearbox was deleted, replaced by a flat machined aluminium plate and the output shaft was shortened by about 200mm. This allowed us to move the engine and transmission back in the car to improve the yaw momentum. The drive shaft was less than 300mm long and this required the engine to be realigned both longitudinally and laterally in the chassis in order to achieve acceptable universal joint angles.

The intent was to make the car as small as possible. This was a mistake, because when the car was sold a year or so later, the chassis had to be extended in the mid section by 100mm to fit the new driver!

Engine choice was ongoing and caused some backtracks in the Design phase. We wanted to use a Honda Coupe 9 engine. This was an air-cooled inline engine and very powerful for its day. Being fitted with 4 carburettors, it developed 116bhp in standard trim and we were sure we could coax some more power. It was lightweight as there was no cooling system, radiator etc which would give a significant drag reduction.

There were two obstacles in the way of using this engine.

- We couldn’t find one in a breakers yard and Honda wouldn’t sell us a new one (even if we could afford it) and,

- We found out the engine rotated ‘backwards’ so adapting it to our Spitfire gearbox and BMC rear axle was beyond our abilities. We had chosen the BMC axle because of the large selection of final drive ratios available. Limited slip differentials or ‘spools’ were not permitted.

Eventually, we settled on a Toyota Corolla engine with significant modifications, giving about 95bhp. This was a safe, reliable engine and was used until CAMS raised the engine capacity limit to 1,500cc, when we fitted a modified Formula Ford engine.

We used a modified Renault R4 radiator, ducted up through the nose. We had lots of room for the duct because the engine had been moved back. Apart from having to fit a small flap on the leading edge of the duct at the first test, we never had overheating problems in all the time we raced the car.

The suspension geometry was very conservative. There was no anti-dive or anti-squat and the steering ratio and Ackermann angle was whatever the Triumph had from the factory.

Pat’s first clubman design

The car was moderately successful as we found our way and worked on reliability and pace. We won a few club races and had some placings in major events.

We also discovered we had an issue with some frame joints cracking and rivets pulling out on the panels, evidence of chassis flex, something I hadn’t anticipated.

At the end of the year, CAMS changed the rules about roll over protection in open cars. In future, open cars must have a full width roll hoop with a diagonal brace and two support struts.

Unlike most of our competitors, who bitched and complained and then welded on a full width structure to the existing chassis, we decided to build a complete new chassis incorporating the new roll structure to stiffen it and made the centre section of the car a little longer.

The revised chassis showing the integrated roll hoop

Having learned the lesson of chassis flex we did some torsional testing, constraining one end of the chassis in the jig and applying torque (with a big steel pipe) at the other end. We had glued lengths of cotton thread across all the bays and when the chassis was twisted, some thread broke and some came loose, letting us see what was happening in the chassis. Replacing some tubes and gusseting some joints made the chassis much stiffer.

Measuring torsional stiffness, wheel to wheel, as is recommended these days, never occurred to us at the time. The new chassis had no cracking problems.

Incidentally, all the chassis were constructed using round and square section mild steel tube and nickel-bronze welded (a form of brazing). No 4130 steel and TIG welding for us in those old days!

We made no changes to the mechanical components or the suspension, which permitted us to assemble the new car using the old components and bodywork. The car was rebuilt in one weekend after the chassis came back from the painter.

A stroke of luck had us sell the old chassis to another friend, who, as I mentioned earlier, had to extend it by 100mm in order to fit into it. That car was eventually built up as a race car, but was not successful in the new driver’s hands.

Our new car was a very different matter, going on to win the state championships for two consecutive years. The stiffer longer chassis with the well proved components was fast and reliable. The car still competes in historic racing, something that is making me feel a bit old.

Inevitably, we were approached to build a car for another competitor, so we set out to build two at the same time. One car was completed but with very different mechanical components, a Ford engine, gearbox and rear axle and it too was quite successful as a 1,500cc car.

However, my friends had developed a fondness for cannabis, so the project got lost and the fourth car was never finished as far as I know. As soon as the dope came in, I was out of there. That was not my scene and working for Yamaha, I was becoming more involved in motorcycle sport. I was involved when Yamaha started supplying the KT100 engine to karting, and had one of the first RC100 Yamaha karts in Australia (three actually) but that is an entirely different story.

That was the end my second involvement with clubman sports cars. Little did I know I would become involved again many years in the future.

In the mid 1990s, a book by Ron Champion called ‘Build your own sports car for as little as £250’ was published, and this revitalised the Clubman sports car scene, now called ‘Locost’ a play on the book name and the original Lotus name.

I didn’t get involved, though I did read the book as I thought there might be some good content for FS teams (there wasn’t!). I was disappointed by what I saw. The construction was more of a ‘High School Engineering Shop’ level than the clever engineering in the previous iterations of these lightweight and fast sports cars.

The Champion school of Locost had more in common with Hot Rodding than it did with race cars. The clever engineering that extracted phenomenal performance from low powered engines were now caught up in the engine performance race, up to and including V8s. The lithe cars had porked up and dumbed down and I was certainly not interested.

However, a workmate became involved and bought a Westfield clone to race. It was more like a 1970’s Lotus 7 and was powered by a Toyota 1,600 DOHC engine. Knowing of my past experience, he asked if I could help him make it more competitive on track. My third era of Clubman involvement was about to begin. It was a short involvement.

I went to look at the car, designed more as a road sportscar, and asked what freedoms we had to modify for racing. When told there were really no restrictions apart from engine size etc, my interest was piqued and I began to look a little closer.

I suggested we move the engine back in the chassis about 250mm to ‘reduce the yaw inertia’ he looked at me quizzically and asked “What’s that”? I suggested we remake all the A arms using spherical bearings and rod ends, whereupon he asked “Why do we need to do that? Rod ends are very expensive”. At this stage I began to understand this wasn’t going to go very far.

I went to a race meeting with him to see what the competition was like. What I saw was a group of mostly ‘wannabes’ rather than serious racers. Being part of the ‘scene’ was more important than the engineering and development, so I knew it would not hold my interest for very long.

The engineering on many of the cars was horrible. Sure, they looked like ‘clubmans’, but the majority were really trying to emulate the look of the original 1960s Lotus seven rather than the much better cars we built in the seventies.

I understood then where it had all gone wrong! When Colin Chapman designed the Lotus 6 and 7 in the 1950s and early 1960s, they were designed to use running gear from the cars available at the time. Normal street cars in the UK were mostly low powered four cylinder, rear drive cars (with the exception of the original Mini).

Those days have long gone. All small cars these days are FWD, so trying to keep the RWD Lotus clones alive parallels the Hot Rodders trying to keep the ’32 Ford Coupe alive.

Were Chapman to have invented the ‘Clubman’ sports car today, it would use a FWD engine/transaxle unit, mounted at the rear, because that’s what is available today!

Sure, some Clubman enthusiasts are building these mid engined cars, called ‘Middies’, but with a few exceptions, clever engineering solutions are not to be seen on these cars.

What now brings this tale somewhat back to Formula Student, relates to the Indian Supra SAE event, where the students are forced by the rules to build a ‘Middy’ type car.

Maruti Suzuki gives a FWD power-train assembly to each team so they have basis of a Supra car. I don’t particularly like this introduction of ‘spec’ racing to Formula Student, but I understand why it has happened in India. The motorcycle engines we take for granted in the West are just not available in India.

A search through the various Locost and Clubman websites will find plenty of pictorial evidence of what I have been saying and I hope our Indian friends can learn ‘What not to do’.

The ‘Clubby’ and ‘Middy’ people can follow their dreams and have fun on the road and track, but the quality of their design and construction is far from what we judges expect at FSG (or Supra SAE for that matter!).

Pats Design Error of the Month

The Locost movement, where the cars are designed and built by amateurs, is a rich source of examples of what not to do.

Look at this, for instance...

This car will break on the road! This design solution for the lower A Arm is pretty common, and sooner or later this happens...

Another solution beloved of the fraternity is to use a bush in a tube as the A arm pivot on the chassis. The load in this bush whilst the car is braking is enormous. Often the well meaning amateur will use welded steel tube to make this pivot and eventually, this happens...

The heavily loaded lower inner front joint has split, causing an instant total suspension failure.

That is enough for this month, a massive trip down memory lane for me and hopefully some lessons can be learned from the mistakes I made (look very closely and you will see some rod ends in bending on Pat’s car!)